Plastic recycling faces many challenges, one of which is recycling different types of plastics together, because different materials have different properties. which may not be compatible with each other and each of them should be processed separately. Accurate separation of waste increases production overhead cost, which, despite the environmental problems caused by leaving plastics in nature, reduces the profit margin and, as a result, the incentive to recycle plastics.

Also, different materials are put together in assembled form, which requires time and energy to be separated from each other. For this purpose, Shinshu University researchers investigated the possibility of sustainable recycling of thermoplastic materials so that instead of burying waste that is difficult to separate and is usually buried in landfills, a so-called mixed recycling process can be carried out.

After steel and cement, plastics are the most widely used man-made material and unfortunately, they do not decompose like natural materials. This has led to the unwanted presence of many plastics in the environment. Melting or incineration are the only solutions to dispose of plastic waste, but they cause other problems such as the generation of toxic fumes that lead to global warming. Therefore, a method for melting different plastics together is necessary.

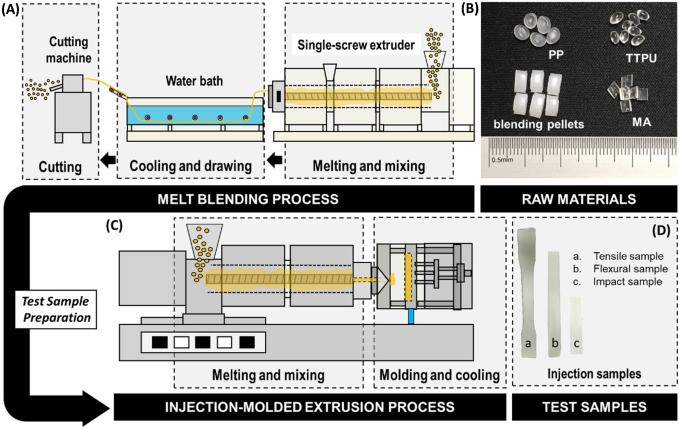

Using the melt extrusion process and the injection molding process, the researchers were able to produce stable recycled thermoplastic mixtures. In order to create stability, uniformity and optimal properties in the final product, they used appropriate compatibilizers. This process makes a lot of plastics regain economic value.

To see the results of this research in detail click here.